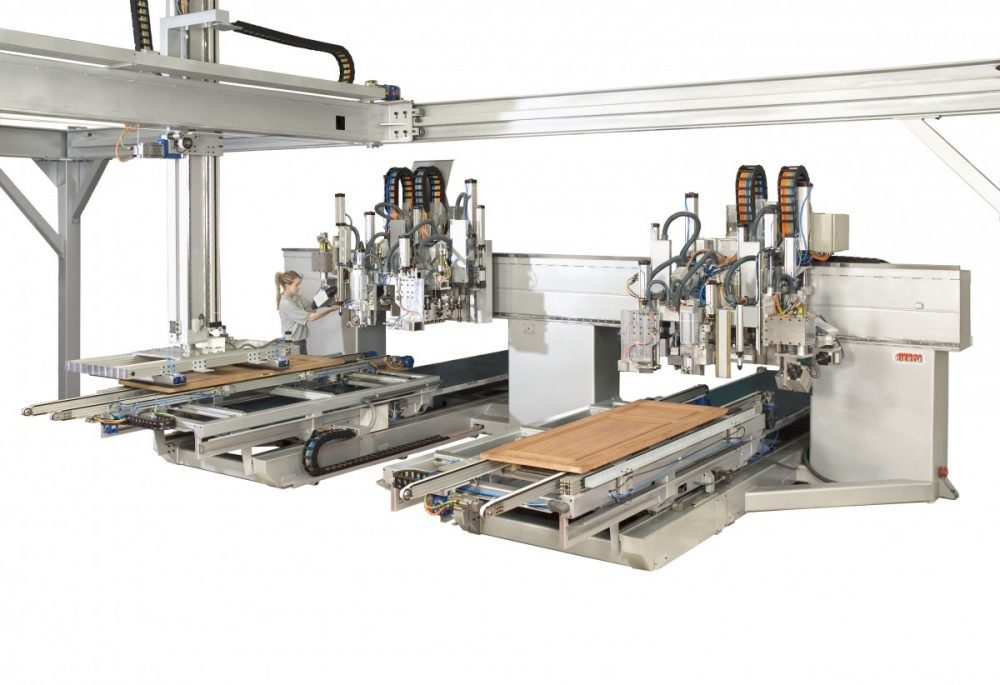

Numeric Control Milling Machine with double movable table and fixed head.

| 1530D | |

| X | 2 x 1500 |

| Y | 3000 |

| Z | 200 |

| Other measures available on demand | |

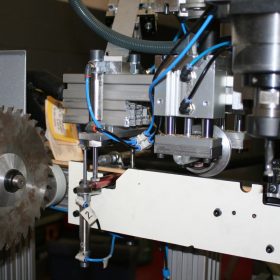

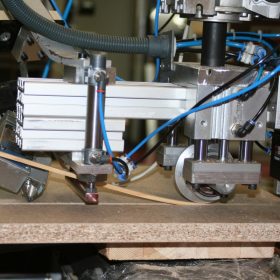

Constructive system:This serie incorporates movable table and fixed head system, adopting the fixed ring format. The constructive system used on this model makes it to be a machine specially designed for aluminum and other non-ferrous resistant materials working, where it is necessary to use big dimensions and heavy tools. The fixed head systema allows us to configurate a multiple aggregate and heavy spindle, without the speed of movement being reduced. Having a long stroke in “Z” axis allows us to machining curved parts, and can install 4 or 5 axis spindles. The subjection is made by controlled opening profiles which incorporate drag bands for the doors, to place them on the correct position for the machining. Machine of great robustness that allows us the machining of all type of materials. BENEFITS• 4 and 5 axis spindle

SECTORS

Click here: PROGRESS to download the details file. |

||

|

|

||

|

DETAILS

Spindle

Tool storage

CNC

Control Desk

Subjection

Aspiration

Lubrication

Tool measurement

SAMPLES

This is the selection we made for this machine