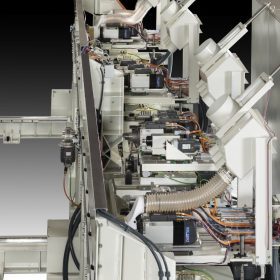

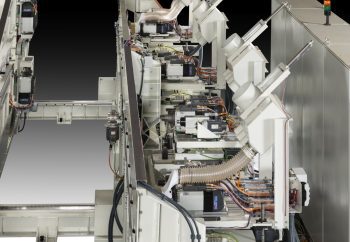

DOOR MACHINING LINE

| MEGADOOR 2.3 | |

| X | 2 X 2700 mm. |

| Y | 1300 mm. |

| Other measures available on demand. | |

Constructive system:Online machine, with independent axes for the machining groups, each of the groups is mounted with independent X, Y, Z axes, so that they can machine independently, doing different jobs, for example hinges and locks simultaneously. To achieve high production and by having two work areas, the machining can be distributed and the ideal cadence achieved. We have vertical and horizontal motors, as well as motors that can machine through the lower part of the door.

The configuration of the head is designed according to the machining needs of the client. |

||

|

BENEFITS

• Floating spindle

SECTORS

|

|

|

|

||

|

MEGADOOR 2.3 A A new version of this range incorporates the possibility of drilling and insertion of cap screws, we call “anubas”. The system is composed by the following elements:

|

|

|

| Click here: MEGADOOR to download the details file. |  |

DETAILS

Spindle

Tool Changer

CNC

Soundproofing

Control Desk

Subjection

Aspiration

Lubrication

Tool measurement

CONFIGURATIONS

This is the selection we made for this machine