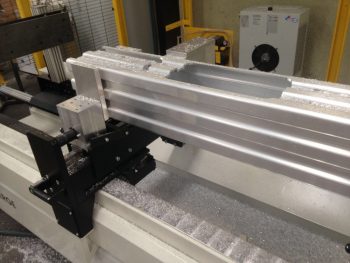

Numeric Control Machine with movable head

| 4040 | 7040 | 10070 | |

| X | 4000 | 7000 | 10000 |

| Y | 400/700 | 400/700 | 400/700 |

| Z | 350 | 350 | 350 |

Constructive system:This serie incorpores a fix table and movable head system, adopting the swan neck system. The subjection is made by pneumatic clamps installed on consoles which can be positioned automatically or manually. Machines can realize displacements of up to 90 mts./min. Those universal machining centers are destinated to aluminum profiles or similar machining. We adapt the machine configuration to the production needs.

Pre-tightening safety cycle for securing the profile, for accident prevention. BENEFITS• 5 axis spindle

SECTORSMACHINING MATERIALS

Click here: Alufast to download the details file. |

||

|

|

||

DETAILS

Spindle

Tool storage

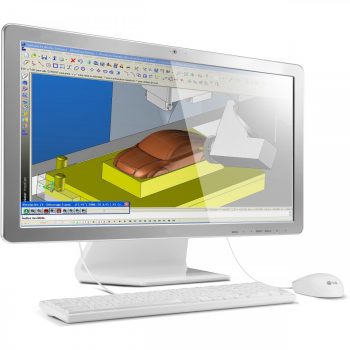

CNC

Control Desk

Subjection

Lubrication

Sprayer

Tool measurement

SAMPLES

This is the selection we made for this machine