| |

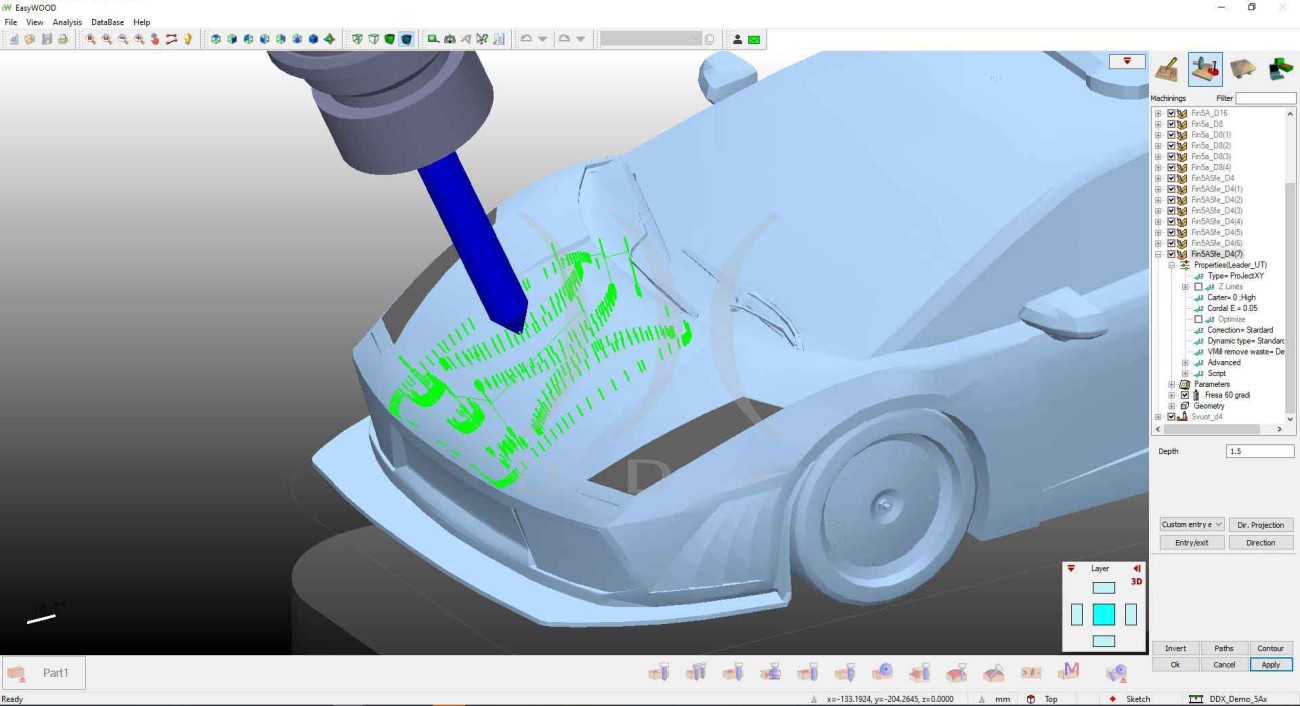

EASYWOOD is the CAD/CAM software solution for wood and similar materials working industry by numerically controlled machining centres.

EASYWOOD is ideal for:

- panels;

furnishings;

true shape nesting;

folding;

IGES, STL, DXF, RHINO import;

3D modeling;

3, 4 and 5-axis machining;

automatic vices and vacuums management;

chip-guard hood management;

aggregate management, also for undercut machinings;

3D simulation;

collision detection;

virtual milling.

EasyWOOD is complete and fully manages the woodworking process: from design to disposition of pieces and underpieces on the bench, 3D automatic collision detection with simulation, machining optimization and program generation.

EasyWOOD, linked to DDXNest, manages geometric shapes nesting both interactive and automatic.

Thanks to the plug-in EasyBEAM, the software machines beams, wooden structures and roofs; the plug-in EasyWALL allows to machine panels.

EasyWOOD is structured into four different steps: Design, Tools and Machining Management, Table and Pieces Disposition, NC-Code Generation.

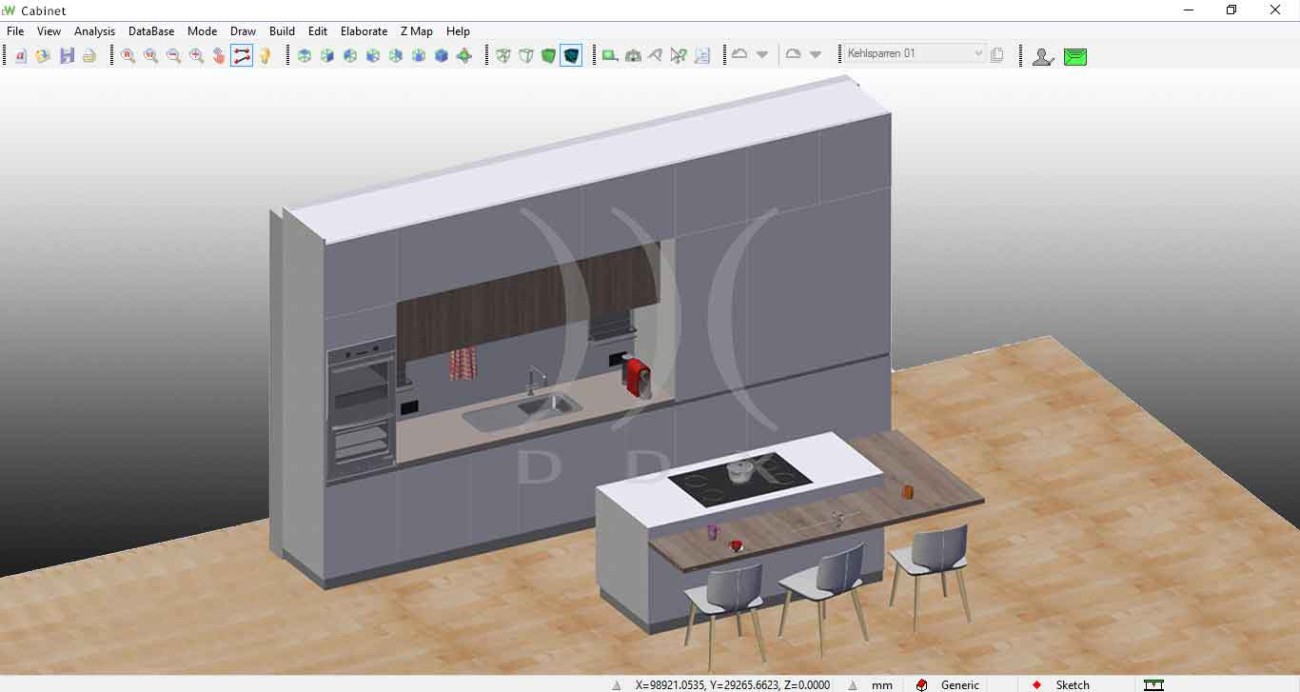

1. Design

With EasyWOOD it is possible to design free geometrical entities and to design from predefined parametric models (libraries): vanity tops, kitchen tops, openings, tables, etc. EasyWOOD imports 2D and 3D standard formats: DXF, IGES, STL and RHINO (3DM) and allows surface definition by laser scanning (point file). The software imports grayscale images and makes Z-Map, vectorization or polymesh. EasyWOOD includes 3D view and photo-realistic rendering of the project and the interactive modification and elaboration of designs thanks to the function cut, extend, split, join, interpolate, copy, move, mirror, rotate, delete, etc.

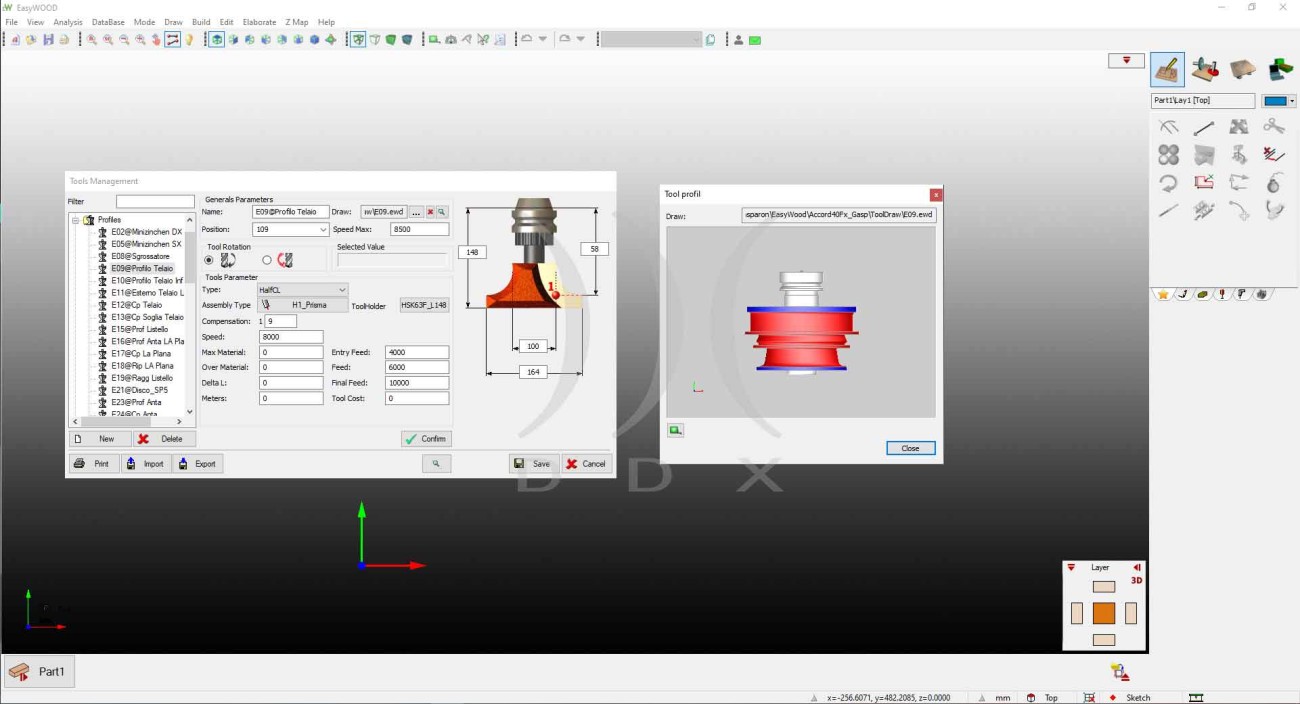

2. Tools and Machining Management

EasyWOOD manages profiled tools, tool holders and aggregates in order to provide a realistic representation of the CNC and to ensure more precision during the machinig. Raw pieces can be defined according to Customer's needs and 3, 4, 5 axis machining can be associated: roughing and surface finishing cycle, drilling, finishing, profiling, empting cycles. EasyWOOD allows machinings and drilling paths optimization. Furthermore EasyWOOD manages roughing optimization considering rough pieces obtained from previous machinings.

3. Table and Pieces Disposition

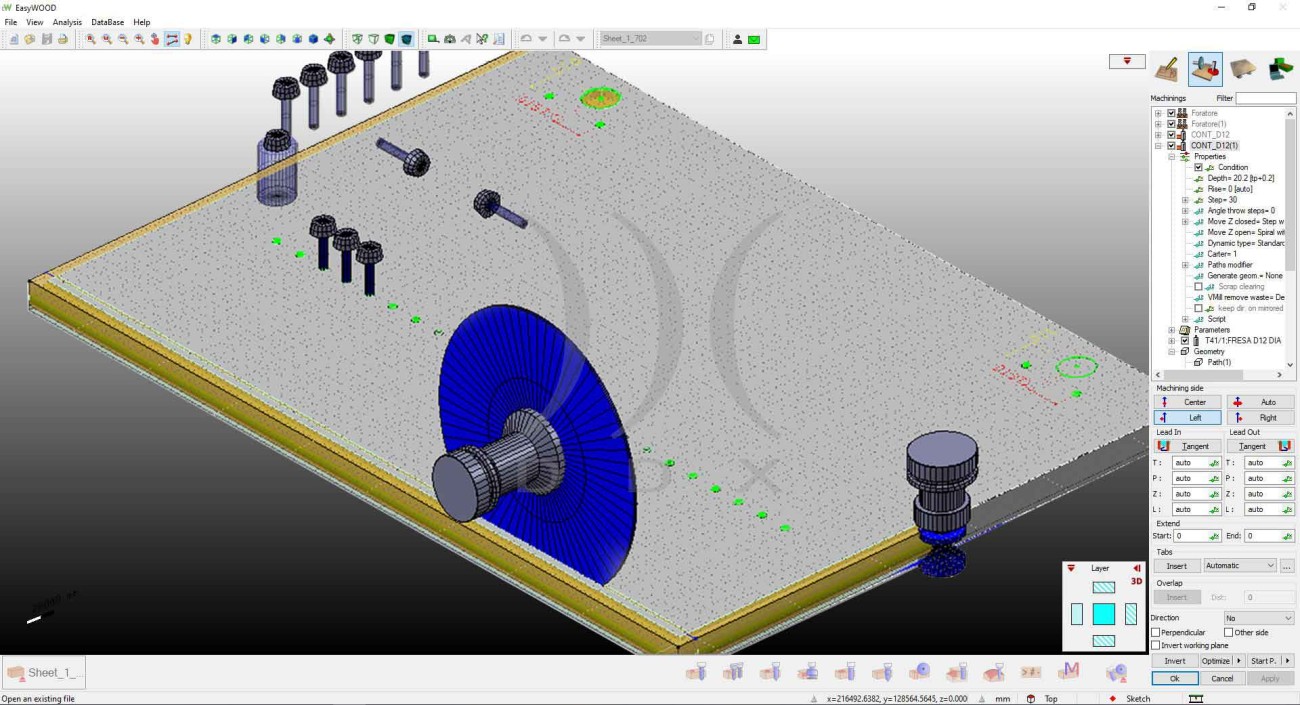

EasyWOOD makes the woodworking process smoother and automatically position pieces and subpieces on the bench. Users can arrange, on the machine table, one or more pieces and relatives sub-pieces (modules, vacuum-pods, vices, references, etc.) with 3D view. Thanks to the customized table it is possible to control every possible interference between subpieces and machinigs. EasyWOOD allows also pendular management.

4. NC-Code Generation

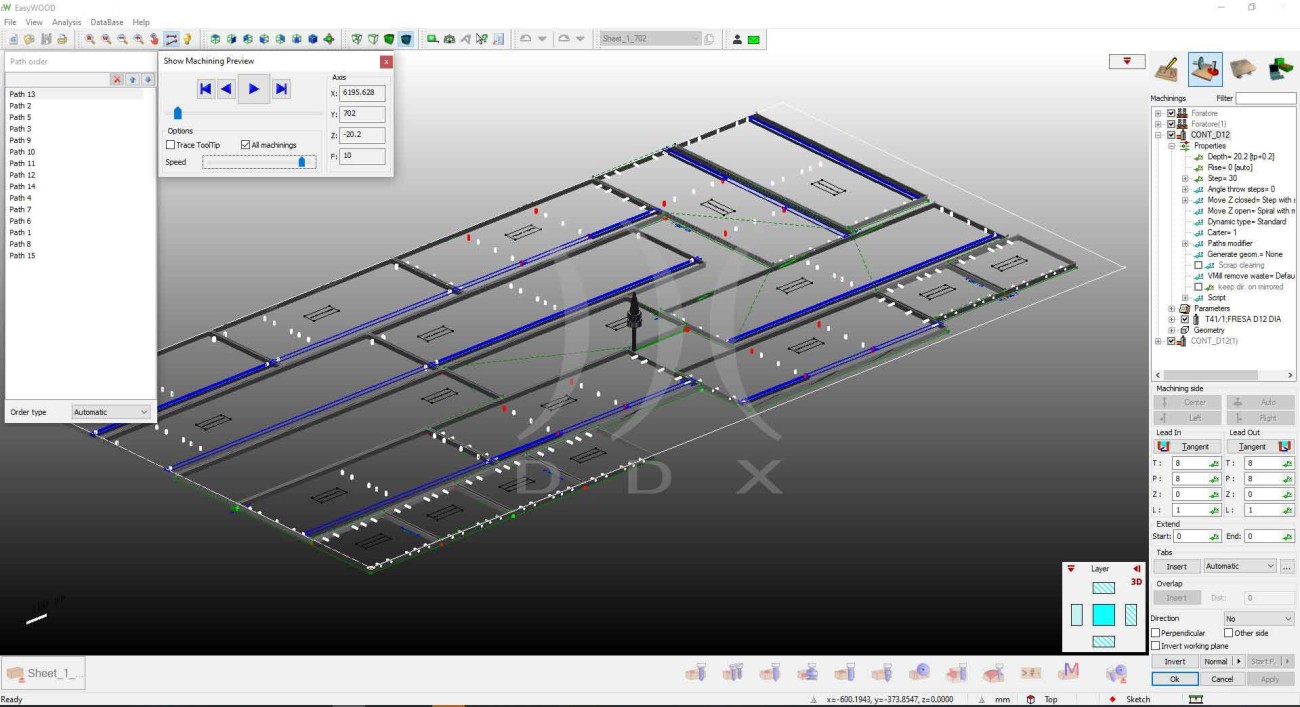

During the last step EasyWOOD calculates automatically machining time, length and costs. 3D simulation of the machining process, idling included, is realistic because it shows the 3D model of the machining centre, of the table, tools, motors, sub-pieces and of the workpiece. Furthermore EasyWOOD allows 3D collision detection between machinings and pieces, subpieces and tools. The automatic collision detection module reduces testing, ensures less material and power consumption and consequently respects the environment. In the end EasyWOOD generates part programs and send them directly to the NC centre of the Customer.

|

|