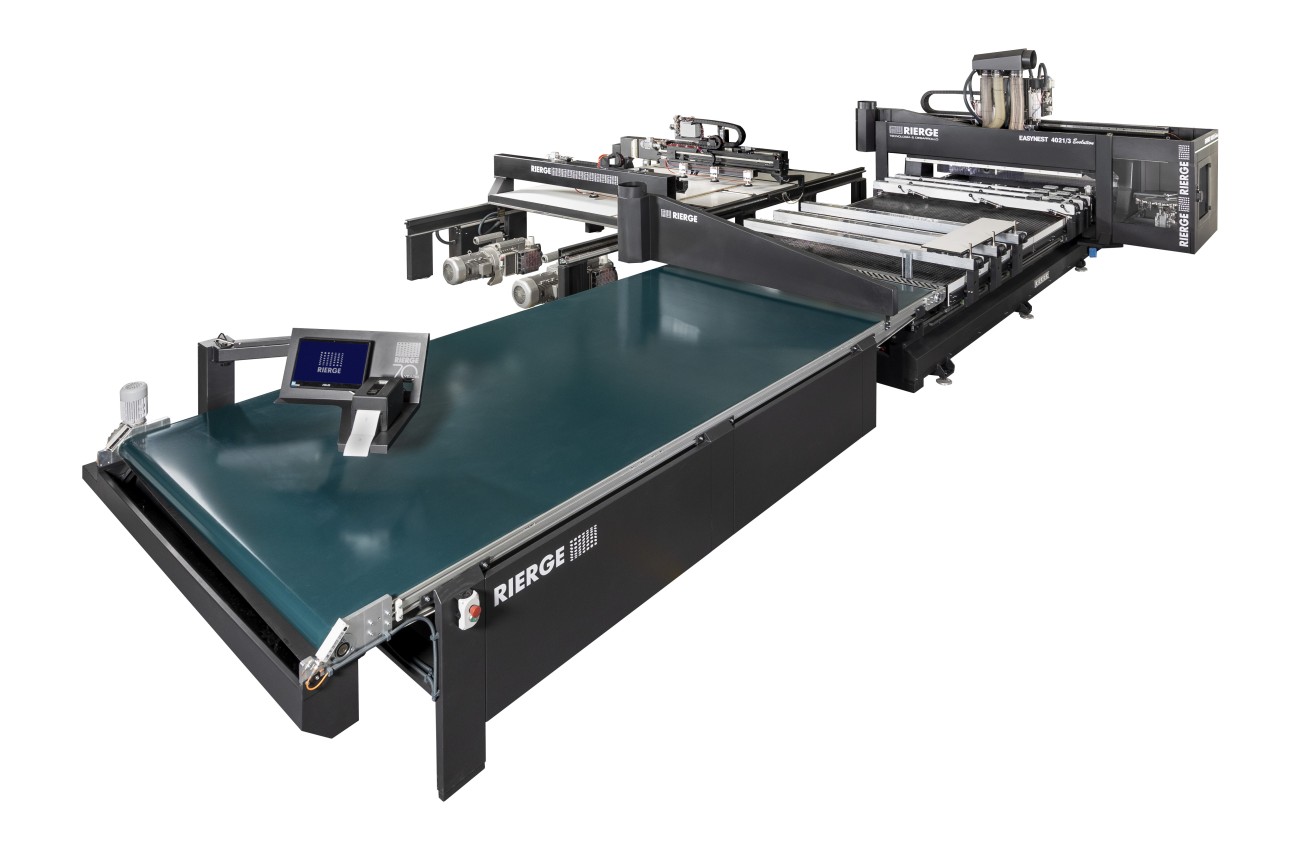

Constructive system:

This serie incorporates fixed table and movable head, adapting the both side tactioned head format, called Gantry system.

This series model has the particularity of incorporating two piece’s subjection systems:

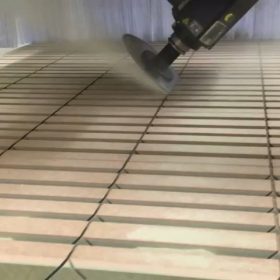

- Through multifunctional table, planned and grooved in squared sections, operation made by the machine itself, which guaranteed a perfect perpendicularity, squared and alignment of the three axis. The working surface is grooved in 22x22mm. squares with 30mm. between centers.

- Through 1000mm. length suction cup consoles which move along and over the multifunctional table with two suction cups on each console and self references points.

This subjection system facilitates us the horitzontal drilling of the pieces cut by Nesting system.

Machines with desplacements up to 80 mt./min.

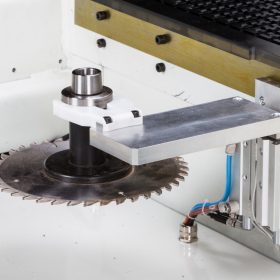

The working spindle composition can be configurated according to the production needs.

Informatic system offers the possibility of installing various software programs, according to the production needs and the autimatization level we want to achieve.

CONFIGURATION OPTIONS

• Floating spindle

• 4 and 5 axis spindle

• 360º Rotating horitzontal engine

• Nesting system

• Independent multidrilling group

BENEFITS

The suction cups consoles incorporation on a Nesting machining centre gives us a greater comfort when making the machining or horitzontal drillings, for what is necessary to elevate the piece from the table. Since now, it was make placing elevators pieces on the table, which required to remove the martyr panel in som cases.

With the system devised and patented by Rierge, you can achieve mechanize the pieces by simply moving the consoles from its parking place and situating them at the desired distance along the working table.

Utility Model no. 201730955

SECTORS

MACHINING MATERIALS

-

-

Resins

-

-

Methacrylate

-

-

MDF Board

-

-

Agglomerate

-

-

Solid Wood

Click here: Easynest Evolution to download the details file.

|