Numeric Control Machine with Nesting System.

| 3018 | 3021 | 4021 | |

| X | 3000 | 3000 | 4000 |

| Y | 1800 | 2100 | 2100 |

| Z | 200/400 | 200/400 | 200/400 |

| Other measures available on demand | |||

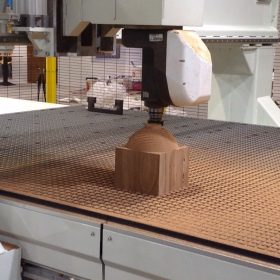

Constructive system:This serie incorporates fixed table and movable head, adapting the both side tactioned head format, called Gantry system. The subjection is made be a grooved resine table and some vacuum shots. This multifunctional table is planned and grooved in squared sections, operations that is made by the machine itself, which guarantee a perfect perpendicularity, square and the three axis alignment. Machines with desplacements of up tu 80 mt./min. The machine can be equipped with a panel dragging loading system to the working area, and once machined this panel, it is retired either one by one, or dragging all pieces at the same time. The working spindle composition can be configurated in accordance with the production needs. The informatic system allows us to install some software, according to production needs and level of automation that we want to achieve. BENEFITS• Floating spindle SECTORSMACHINING MATERIALS

Click here: Easynest to download the details file.

|

||

|

||

DETAILS

Spindle

Tool storage

CNC

Control Desk

Subjection

Aspiration

Lubrication

Tool measurement

SAMPLES

This is the selection we made for this machine