Wooden storers

08/01/2019

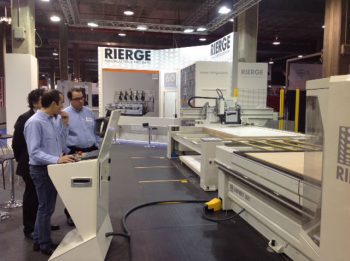

Main wood warehouses have trusted in Rierge for installing CNC machining centers in their board cutting departments, offering a better service to their customers. They are:

- Gabarro Hnos.

- Fustes Closa

- Fustes Montgros

- Fustes Vilanova

For them, we’ve designed a very complete machine for the machining of several types of materials, doors, molds, Nesting works, in order to offer a personalized service to their customers.

Nowadays,they don’t just supply wood, but some other new materials are being integrated both industrially and privatelly uses. This is the case of Solid Surface and the wide range of compact boards and resines, for which, with our CNC machining centers, we also give solutions for perfect finiched pieces, thanks to the robustness of our machines and their electric components we incoporpore to them, as tha fact of having a real industrial numeric control and not a simply axis control card other companies incorpore, even the most known.