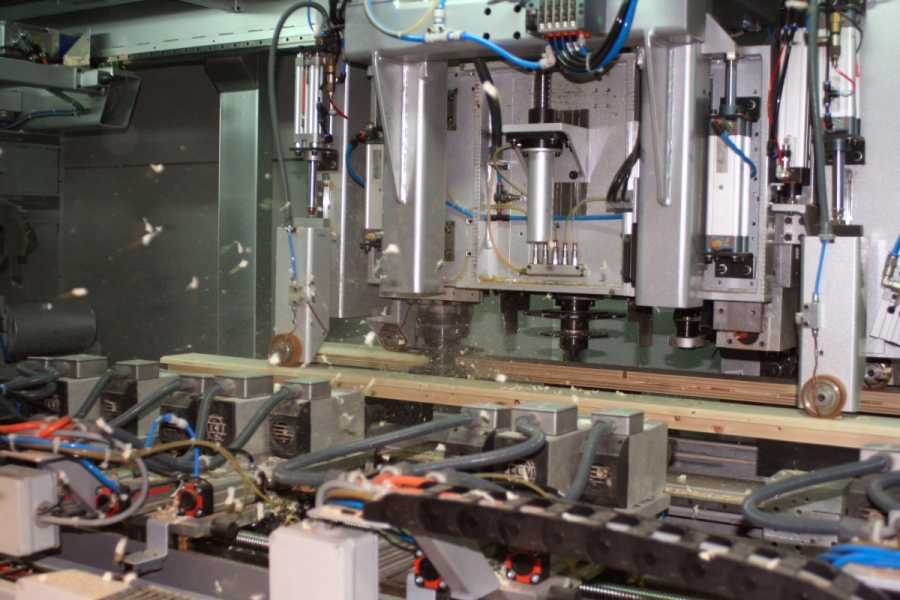

5 simultaneous Working Groups Numerical Control Machine.

|

This model is configurated according to the production needs. The number of controlled axis and machining engines are countless. |

Process:We obtain the door uprights from a molding machine, and by an automatic loading system, the two pieces enter the machine and are positioned at the corresponding point 0, on the suction cups by vacuum. At this time the different heads are positioned independently and simultaneously and proceed to perform the different machining process. The loading and the discharge of both pieces is performed automatically, and the subjection is carried out by pneumatic clamps or vacuum suction. These elements are automatically positioned in the right place to avoid any collision with the cutting tools. This machine is composed of 5 groups of motors, each group has independent cartesian axes controlling up to 22 axes, working independently of each other and simultaneously, which allows different functions to be performed simultaneously such as cutting, grooving, milling, splitting, gouging, drilling…

BENEFITS• The machine is faired for the personnel protection

SECTORSClick here: MECACERC to download the details file.

|

||

|

|

||

DETAILS

Spindle

|

The spindle is configurated according to the needs of the customer. This machine is composed pf 5 groups tha work simultaneously and depending on the machining that we need to perform, we will install on type of motor or another.

|

CNC

Control Desk

Subjection

Aspiration

Lubrication

CONFIGURATION

SAMPLES

This is the selection we made for this machine