|

The irruption of new materials in the civil construction sector, as well as in general industry and, in particular, in the aeronautical sector, has made the manufacturers have to adapt the machines, to work all that range of materials, which, because of its composition, requires a special treatment in terms of tool turning revolution, advancement and hardiness of the structures to give the machines a good dynamic and vibration absorption. Let’s define some of the materials that today are forming part of our sector: |

|

|

Phenolic resinsThey’re used in the manufacture of sports, school and office furniture. In different compositions it’s an ideal material for laboratories and hospitals, both in the manufacture of furniture as well as lining interior and exterior walls, streed furniture, playgrounds… They are also used in the automobile and aeronatics insutry, as electrical insulation, in the construction of railroads and an endless number of uses. It is resistant to extreme temperatures, has a good electrial properties and is resistant to solvents, acids and abrasion; It also has a thermal stability, anticorrosive properties and insulation, depending on the type of resin it’s done, and its concentration. |

|

Composites panelsThese panels are an aluminum compound that allows to be bent or curved. They are composed of two sheets of aluminum and a thermoplastic core. Due to its properties, it can be installated in the exterior, because it avoids corrosion, is fire resistant and has sound and vibration insulating properties, and it absorbs deformations caused by seismic events.

There is a whole range of colors and finishes, and thanks to its malleability, offer us the possibility of executing desing works. Normally, to install it on metal structures a tray is formed by machining to hang on the rails placed on the facade. |

|

HoneycombAluminum honeycomb structural panels with anticorrosive treatment, aluminum foil on both sides and covered with protective plastic. The main features of these sandwich panels are rigidity, lightweight, as well as perfect acoustic and thermal insulation that, along with the wide range of options that allow manipulation, machining, bending and folding, makes it and ideal product for architectural and railway applications, in the naval and industrial sector. Partition screens, floors, ceilings, doors, platforms and all kind of furniture. The interior of ships, trains, airplanes, buses, caravans and other means of transport are manufactured with this type of panels. It can also be applied in other sectors such as lifts, cleanrooms, industrial machinery… |

|

CorianIt’s a blend of natural minerals and acrylic polymer. It is made in the form of plates and shapes (like sinks and washbasins), with a wide range of colors. It is a versatil design material with a multitude of applications in a wide range of sectors, for example, at home for kitchens and bathrooms, furniture and lighting elements. It can also be found in stores, restaurants, hospitals, offices… and in almost any space where design and lastinc performance are important. |

|

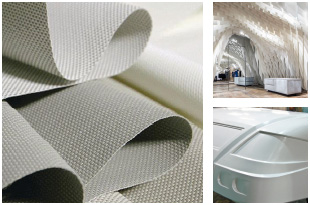

FiberglassFiberglass is the result of mixing the glass mesh with an Epoxy resin, wich is initially liquid, and when it solidifies is able to maintain the final or acquired shape of the mold. The characteristics of fiberglass are: • Excellent thermal insulation Because of the characteristics of this material, fiberglass is used in many industrials and artistic uses. Among the most important uses we find: crafts or DIY, nautical pieces that include surfboards, wind-surf, sailboats, boats, etc. Also used in art for sculptures and complex pieces. Due to its properties (it’s moldeable with scarce resources) it is and ideal material for those people who wish to work fiberglass. |

|

Carbon fiberThe carbon fiber (CF) was initially developed for the space industry, but now, when lowering prices, it was spread to other fields like the transport industry, aeronautics, high competition sport and, lately, we find CF up to wallets and watches. The CF is composed of many strands of carbon in vein form. There are many classes of CF with diverse properties, adapted to many applications. Its resistance is almost 3 times superior to the steel and its density is 4.5 times smaller. Other properties very appreciable in the carbon fiber are resistance to corrosion, fire and chemical inertia and to electroal conductivity. It retains its shape in the face of temperature variations. Carbon fiber is a polymer converted to fiber. It’s used in the transport industry , especially aerospace and aeronautics, but every day it’s taking more prominence in the automotive industry. |

|

Sandwich PanelA typical sandwich panel has a three-layer structure. Rigid surface, with a relatively high modulus of elasticity are kept at a distance by a light core, which has sufficient bending stiffness to withstand most cutting forces. The core also acts as a highly effective thermal insulation layer. Sandwich panels are now available for a wide variety of applications: facades, roofing, false ceilings and interior partitions, especially in industrial buildings with high thermal insulation requirements. Uses in civil works: industrial buildings, airports, administration buildings, houses and prefarbricated houses, exhibition halls, hotels, laboratories and clean rooms, operating rooms, painting rooms, power plants, sports centers, big malls and housing. Uses in the food industry: cold rooms, conservations rooms, freezing tunnels, process rooms, clean rooms, the manufacture of vehicles intended for the transport of refrigerated food…

All these materials have in common that they are almost unalterable by humidity, are resistant to corrosive agents and do not need maintenance, so they’re ideal for exteriors and interiors where the environments are aggressive and a scrupulous cleanliness is required for reasons of contagion. At the same time, they are pleasant materials to the eye with great ranges of textures and colors, in addition, they allow to be screenprinted so the installation can be costumized to taste of client and that allows the realization of complex mounts. |

We have machining centers specially designed for the machining of these materials, in addition to a wide experience to them.