5 axis Numeric Control Machine. Fixed table and movable head.

| 4018 | 5018 | |

| X | 4000 | 5000 |

| Y | 1800 | 1800 |

| Z | 300/500 | 300/500 |

| Other measures available on demand | ||

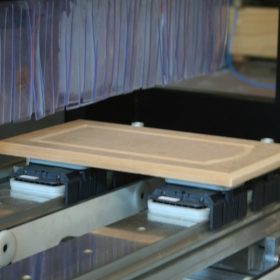

Constructive system:This series incorporates the fixed table and movable head system, adopting the traction on axis “X” bothside the table with two independent engines format, called Gantry system, which allows us to reach axis “Y” length of up to 2500 mm. and superior than 7000 mm. on axis “X”, ensuring this way a high precision and the absence of machining vibrations. The subjection is made by clamps-holder console, or a multifunctional table. Machines with desplacements of up to 90 mt./min. BENEFITS• 4 or 5 axisd spindles SECTORSMACHINING MATERIALS

Click here: JST-V to download the details file.

|

||

|

||

DETAILS

Spindle

Tool storage

CNC

Control Desk

Subjection

Aspiration

Lubrication

Sprayer

Tool measurement

SAMPLES

This is the selection we made for this machine